Quality Policy

Quality Assurance

We are guided by a set of stringent quality control policy adopted by the management. According to this, we seek to maintain qualitative production system at every stage of the manufacturing. After sales service is the integral part of our quality control policy. Besides, our products are tested on the parameters like Abrasion resistance, Length and diameter, Corrosion resistance, Tensile strength, Metric bolt strength and Thread dimensions.

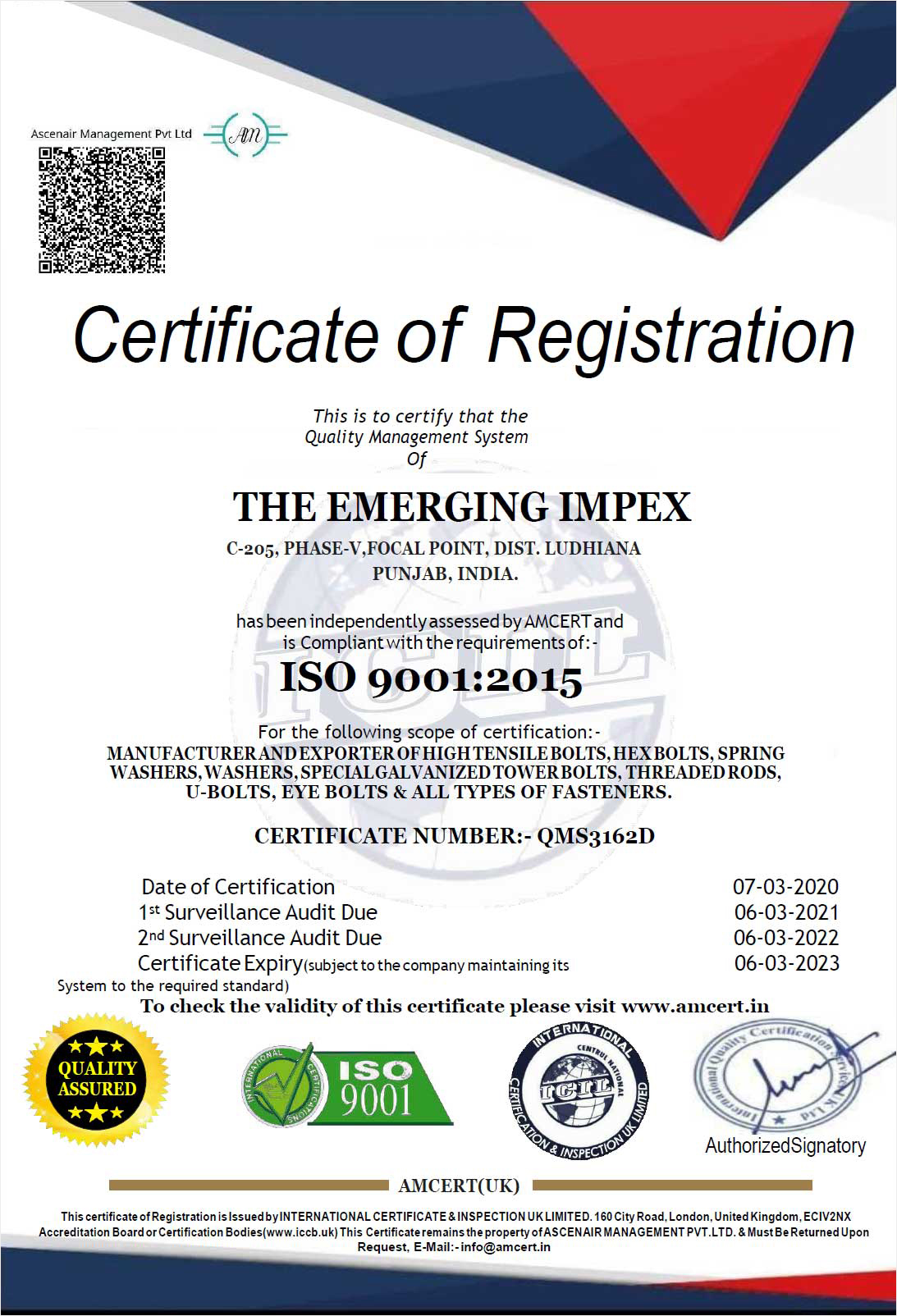

ISO 9001:2015 Certification

Being an ISO certified company and the leading company awarded by the government of India with the honor of "One Star Export House," In addition to these credentials; Facing the fierce competition from India and other countries, TEI's main goal is to satisfy customers' demand to its fullest and achieve on time delivery at all times. On the other hand, in order to locate more business opportunities in the U.S.A market, TEI Had participated in exhibition at the National Industrial Fastener & Mill Supply Expo in October 2016. We know and understand the needs of US clients and our step-by-step quality procedures & control of product manufacturing at every stage help us retain the confidence in our clients worldwide.

Incoming Inspection

Incoming Raw Materials are the foundation for the final product. We make sure that we start with the best raw materials. Our suppliers are well-informed with our quality requirements.The quality assurance system is guided by principles that support our unique working culture which incorporates respect, self management, open communication and creativity.

Raw Materials are inspected for

- Physical and chemical properties, material which does not meet the required specification is rejected.

In-Process Inspection in melting process

- Samples are checked during melting process and during refining process. Heats are cast only when the required composition is met.

Finished Goods Inspection for Billets

- One sample is collected from final product and analysed in spectro & Macro/ Micro Lab.

- One sample from each strand is collected for macro analysis, internal defects and soundness of billets is checked by magnification.

Finished Goods for Bright Bars are inspected

- Surface Finish

- Final Mechanical Properties

- Mercury Contamination,Macro and Micro Properties,Inter Granular and Corrosion Properties

- Packing,Color Coding,Marking